EMBODIED CARBON

Embodied Carbon Emissions from Construction Materials

As part of our renewed SBTi-validated GHG reduction targets, the Group has committed to reduce the embodied carbon1 of our building materials by 41% compared to a 2016 baseline by 2030. Furthermore, we anticipate carbon-intensive construction materials, such as steel and cement, to become increasingly costly and have begun planning for usage of more sustainable alternatives in the future. We also monitor and report the embodied carbon performance of our projects against our SBTi-validated targets. This addresses the Group’s Scope 3 emissions and wider supply chain management strategy.

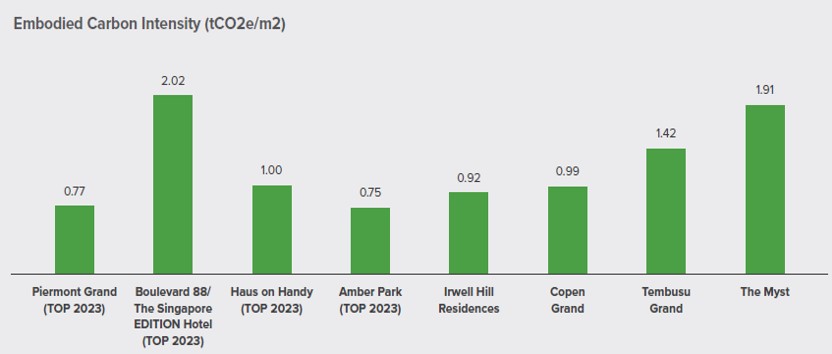

An interim 2023 target of a 21% reduction in embodied carbon of building materials was set. We track the performance of these projects against the current interim target,2 and raise the next interim target where necessary to map our phased progress towards the 2030 SBTi-validated target of 41% reduction. The Group obtained Temporary Occupation Permit (TOP) for Piermont Grand EC, Haus on

Handy, Boulevard 88/The Singapore EDITION Hotel and Amber Park in 2023. These projects collectively achieved an average 33%3 carbon reduction amounting to carbon intensity of 1.10 tCO2e/m2.

Managing Impact of Top Building Materials

With cement manufacturing and steel production responsible for around 7%4 and 7-9%5 of global carbon emissions respectively, it is imperative to reduce reliance on these materials. We apply a circular economy approach to materials used for our development projects. To close the waste loop, recycled construction materials, such as recycled steel and concrete are used wherever applicable. We also encourage the use of alternative low carbon materials at our sites and are constantly exploring innovative building materials and methods to facilitate our transition to net-zero. In November 2023, Amber Park was awarded the Structural Steel Excellence Award which celebrates steel structural engineering excellence in demonstrating potential in terms of efficiency, cost effectiveness, aesthetics and innovation.

Since 2016, the Group has been tracking and reporting the top five building materials and embodied carbon intensities of the construction materials used in our property development activities to determine the wider carbon life cycle impact of our projects. The embodied carbon emission intensities for our projects have been derived using BCA’s Carbon Calculator, based on the type and quantity of construction materials used.

Carbon Emissions from the Group

In 2023, the Group attained a reduction of 61.6%6 absolute carbon emissions in 2023, and aligned our SBTi-validated target to reduce absolute Scope 3 GHG emissions from investments by 58.8%, including hotels managed by our key subsidiary, M&C. This reduction in part due to lower emissions resulting from the accounting deconsolidation of CDL Hospitality Trusts portfolios, alongside other carbon emission reduction and energy efficiency initiatives. We will continue to reduce M&C’s carbon footprint, recognising its significant contribution to our carbon emissions.

The Company’s green construction initiatives

| Materials | Initiatives | Benefits |

| Concrete (Including granite, cement and fine aggregate) |

|

|

| Steel |

|

The Company’s top five building materials

Please slide left to view more.

| Top Five Building Materials (Tonnes) | 2019 | 2020 | 2021 | 2022 | 2023 |

| Granite | 77,854 | 77,885 | 71,214 | 42,480 | 933 |

| Fine Aggregate (Sand) | 58,846 | 58,921 | 53,046 | 30,546 | 7,374 |

| Cement | 20,674 | 21,410 | 18,289 | 18,706 | 28,912 |

| Steel | 12,823 | 12,548 | 13,028 | 11,948 | 29,260 |

| Ceramic & Porcelain Tiles | 2,227 | 2,160 | 2,086 | 1,838 | 2,727 |

| 1 | Embodied carbon refers to the carbon dioxide equivalent or GHG emissions associated with the non-operational phase of a building and has become an increasingly important area for the built environment sector to address. It includes emissions caused by extraction, manufacturing, transportation, assembly, maintenance, replacement, deconstruction, disposal and end-of-life aspects of the materials and systems that make up a building |

| 2 | Based on the life cycle of the Group’s project developments, embodied carbon data for building materials is only available upon TOP attainment |

| 3 | The calculation is based on the best available information on emission factors for building materials and industry accepted approaches at the point of reporting. These changes could have also contributed to this reduction |

| 4 | Cementing your lead in the green transition | McKinsey |

| 5 | Steel industry makes ‘pivotal’ shift towards lower-carbon production | News | Eco-Business | Asia Pacific |

| 6 | There have been changes in our investment portfolio as well as emission factors applied between 2016 and 2023. The reduction would be 58.7% when calculated on a comparable basis |